Enquiry Form

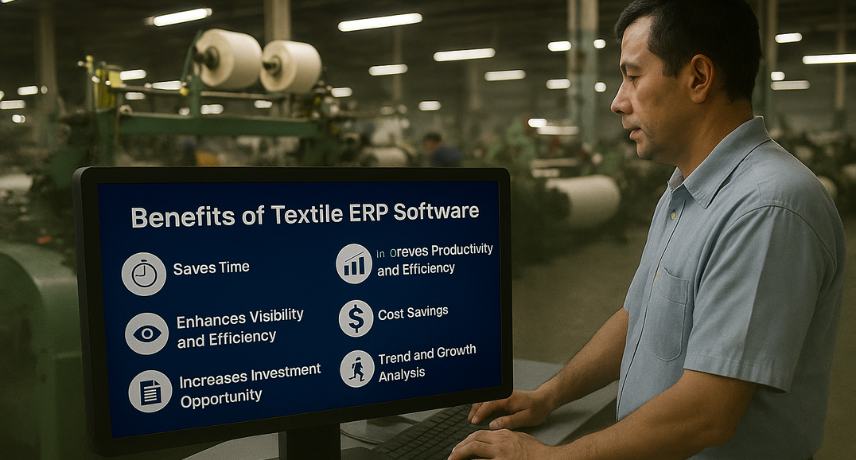

Top Benefits of Textile ERP Software: Boosting Efficiency & Reducing Costs

Imagine this: your textile manufacturing operation is running at capacity, you are dealing with orders in production, and your inventory levels are balanced. No more emergency calls about a shipment missing or out of materials. This is not a dream; this is what happens when some textile companies implement the appropriate ERP software solution.

The textile industry faces different challenges and demands than generic business software can handle. From managing complex supply chains in different countries to tracking complex production processes with dozens of variables, textile manufacturers require industry-specific solutions. That is where textile ERP software takes the chaos of operating a textile facility and brings it into structure.

What Makes Textile ERP Software Essential for Modern Manufacturing?

Textile ERP systems are specially configured to manage the maze of fabric manufacturing, garment manufacturing, and fashion retailing processes. These solutions, in contrast to typical enterprise software, are made aware of the specifics of textile processing, starting with fiber sourcing through delivery of the final product.

The textile business has very low growth and stiff competition all over the world. Any company that does not optimize its operations runs the risk of being left behind by the competition, which is using technology to cut costs and enhance efficiency. The challenges are tackled by the modern textile ERP software.

Streamlined Supply Chain Management

Enhanced Vendor Coordination

The in-built vendor management capabilities ensure that it is simple to deal with suppliers who operate at different times. Your procurement department can also monitor the performance of the suppliers and keep track of delivery schedules and quality through a single dashboard.

Automation of the purchase orders will assist you to make sure that you will never be caught short of crucial supplies and to avoid unnecessary inventory costs. The system gets to know your production patterns and makes suggestions for the best reorder points based on past experiences and future orders.

Real-Time Shipment Tracking

Have the exact position of your materials at any given time. Whether it is raw cotton that has moved out of ports or finished fabrics in your facility, full visibility removes unexpected situations and allows you to solve problems proactively.

Optimized Production Planning and Scheduling

Intelligent Resource Allocation

The results of improving the efficiency of the textile ERP are realized right away in the production planning. The software considers the capacity of a machine, the availability of the workers, and the stocks of materials, then constructs the best production schedules that ensure maximum throughput and least waste.

Bottleneck identification is automatic and enables production managers to correct the problem before it can affect delivery dates. This aggressive strategy lets your production lines be at their best and your customers satisfied.

Integration of Quality Control.

Inbuilt quality management modules monitor the degree of defects and adherence levels and create elaborate quality reports. When problems are detected, the system identifies the point at which and at what time the problems were experienced, which makes it easy to take corrective action.

Significant Cost Reduction Opportunities

Inventory Optimization

Unmoved inventory is a waste of working capital and costs of storage. The Textile ERP program involves the use of sophisticated algorithms to keep stock at the optimal level and minimize carrying costs whilst still maintaining production continuity.

The system keeps track of inventory based on a variety of attributes such as color, size, weight, and quality grade. Such granular visibility stops expensive production delays due to the lack of materials.

Waste Minimization

Smart cutting optimization is used to minimize the amount of fabric wasted by calculating the optimal layout of pattern pieces. A few textile firms report savings of 15-20 percent of fabric waste following the implementation of ERP solutions.

Monitoring of energy consumption also reveals ways of saving on utility bills by scheduling high energy-consuming processes at off-peak periods.

Improved Inventory Control and Management

Multi-Location Visibility

Inventory management in various warehouses, production plants, and retail outlets becomes easy. Real-time synchronization is used to give the right level of stock irrespective of the location of items.

Automated location-to-location stock transfers maximize inventory allocation depending on the demand trends and production needs

Lot Traceability

Full tracking of the raw materials to the finished products will guarantee that all regulations of the textile industry are respected. You can easily detect problematic products and take suitable measures when quality concerns arise.

Enhanced Customer Service and Order Management

Faster Order Processing

Automated order processing and order entry diminish manual errors and decrease the time to finalize the order. The ability to integrate with electronic commerce platforms allows the flow of orders through online channels into the production systems without any problems.

Customer service staff can obtain immediate access to the status of orders, inventory availability, and delivery schedule, and therefore, they can share adequate information right on the spot.

Delivery Performance Improvement

Delivery time rates usually increase (25-30%) when ERP is implemented. Shipping delays are normally caused by a lack of proper planning of production and inventory management.

Data-Driven Decision Making

Comprehensive Reporting and Analytics

Inbuilt business intelligence tools will give you a clue about all your textile activities. Based on production efficiency indicators for the customer profitability analysis, the decisions are no longer made by guessing.

Dashboards that can be customized provide executives and managers with immediate access to key performance indicators pertinent to them.

Predictive Analytics

High-end ERP systems employ machine learning to forecast demand trends, observe possible quality concerns, and suggest process enhancements. This is a proactive solution that assists textile companies to be ahead of the game.

Integration Capabilities and Scalability

Seamless Third-Party Connections

The current textile ERP software is compatible with the existing systems, such as accounting software, CAD systems, and e-commerce platforms. This connectivity will remove silos of data and will provide a free flow of information within your organization.

Custom integrations API features allow connecting to special textile equipment and software tools.

Growth-Ready Architecture

Textile ERP solutions are easily scaled to accommodate business expansion on a cloud basis. With new users, new locations, or new functionality, you do not need to spend a lot of money on new hardware or take on a long implementation project.

Conclusion:

ERP software in the textile industry has benefits that go a long way beyond mere process automation. The general operational efficiency, inventory cost reduction, and customer satisfaction metrics generally improve by 20-35, 15-25, and 100 percent, respectively, in companies that implement comprehensive textile ERP solutions.

The key to success lies in the ability to select an ERP system that requires particular adjustments to be used in the textile operations and not attempt to force generic business software to be tailored. The difference lies in the specialized features and industry-specific functionality that can make the difference in marginal improvements and transformational results.

Need to change your textile business? Relate with the Software in Demand to fully customized Textile ERP Software to meet your needs in the manufacturing sector. Our practice team also assists textile firms in the region to adopt ERP systems that will provide quantifiable benefits within the first year

Frequently Asked Questions

1. What is the average time taken to implement textile ERP?

The implementation time depends on the size and complexity of the company; however, with the right preparation and resources, most textile ERP projects can be completed in 3-8 months.

2. Does textile ERP software have the ability to integrate with current accounting systems?

Yes, the current ERP systems of textiles can be used to have strong integration with such widely used accountancy systems as QuickBooks, SAP, and other enterprise systems.

3. What is the average ROI on the textile ERP software?

In 12-18 months, most textile companies achieve positive ROI by cutting operational costs, enhancing efficiency, and better inventory management.

4. Can a textile manufacturer use cloud-based ERP?

Cloud-based textile ERP is highly scalable, less expensive to start, and has a simpler maintenance process than on-premise products, which is why most textile operations should use it.